Tlhaloso

| Mokhoa | ho tiisoa ka mahlakoreng a mararo, li-servos tse supileng, lijo tse 'ne, servo ea mochini o ka sehloohong, sehiloeng habeli. Ka sesebelisoa sa ultrasonic. |

| Lisebelisoa tse so ntlafatsoe | BOPP, CPP, PET, NYLON, filimi ea laminated ea polasetiki, filimi e phatlohileng ea libapali tse ngata, aluminium e hloekileng, filimi e entsoeng ka aluminium ea aluminium, filimi e entsoeng ka pampiri ea polasetiki. |

| Max. mokotla o etsang lebelo | 180 nako / mets |

| Lebelo le tlwaelehileng | 120time/min (tiiso ea mahlakore a mararo 100-200mm) |

| 4 boholo. material out feeding line lebelo | ≤35 m/min |

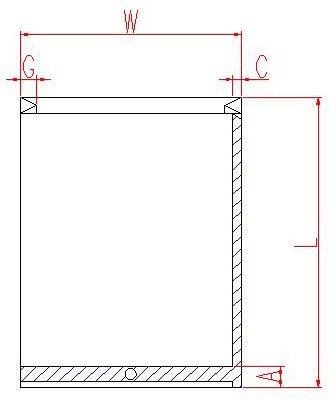

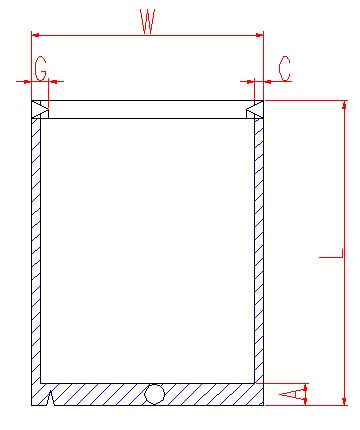

| Boholo ba mokotla | |

| Bophara | 80-580 limilimithara |

| Bolelele | 80-500 limilimithara (mosebetsi oa phepelo e habeli) |

| Bophara ba ho tiisa | 6-60 limilimithara |

| Mokhoa oa mokotla | mokotla o tiisang mahlakore a mararo, Mokotla o emeng, mokotla oa Zip le ho tiisa mahlakore a mane |

| Boholo ba moqolo oa thepa | Ø 600*1250 limilimithara |

| Ho beha ka nepo | ≤±1 limilimithara |

| Thermal sealing thipa bongata | Lihlopha tse 'ne tse tiisitsoeng ka thermal sealing, lihlopha tse' nè tse holim'a mokhoa oa ho pholile o otlolohileng. Lihlopha tse peli holim'a lithipa tse koalang mocheso oa zipper, lihlopha tse peli tse pholileng. Lihlopha tse tharo tse holim'a tiiso e tšekaletseng ea thermal, lihlopha tse peli tse holim'a sethala sa ho pholisa se tšekaletseng |

| Bongata ba taolo ea mocheso | 22 litsela |

| Lethathamo la litlhophiso tsa taolo ea mocheso | e tloaelehileng le ho fihlela ho 360 ℃ |

| Matla a mochini o felletseng | 45KW |

| Kakaretso ea boholo (bolelele*bophara*bolelele) | 14100*1750*1900 |

| Net boima ba mochine o feletseng | hoo e ka bang 6500Kg |

| Mmala | 'mele oa mochine o moholo o motšo, sekoahelo ke lebese le lesoeu. |

| Lerata≤75db | |

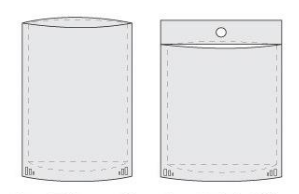

Tiiso ea mahlakore a mararo

Ho tiisa mahlakore a mane

Ho tiisa mahlakore a mane

Ema mokotla

Ema mokotla o nang le zipper

Tlhaloso le li-parameter tse amehang

| Sesebediswa sa foreime sa ho phutholla | |

| Sebopeho | ertical automatic error e lokisa sebopeho sa ho phutholoha |

| Taolo ea tsitsipano | |

| Braking ea matla a Magnetic | |

| Mohaho oa ho fepa | |

| Mokhoa oa ho laola | mofuta o phaphametseng oa motjeko oa motjeko o tsamaisang sensor o laola lebelo la ho fepa |

| Nip roller e tsitsitseng e tsitsitseng e tiileng (e nang le shaft e atolosang moea) | |

| Phoso ea ho lokisa taolo (EPC) | |

| Sebopeho | screw rod secondary adjustment, K shelf e phahamisa le ho oa |

| Khanna | Solid-state relay e khanna enjene ea synchronous e lebelo le tlase |

| Phetiso | khokahanyo ea tšepe ea shaft |

| Mofuta oa taolo | ho bonahatsoa ha transducer ea motlakase, taolo e ikemetseng. |

| Ho nepahala ha ho latedisa | 0.5 limilimithara |

| Sebaka sa ho fetola | 150 limilimithara |

| Likotoana tse fapaneng tsa lehlakore holimo le tlase | |

| Sebopeho | roller's single end spring pressing structure |

| Phetoho | ho lokisa ka letsoho |

| Sesebelisoa sa ho tiisa se otlolohileng | |

| Sebopeho | paatsepama e bontšang tšepe tobetsa, tsidifatso kopano selemo tobetsa sebopeho |

| Khanna | mochini o ka sehloohong o khanna coupling rod ea eccentric mechanism ho etsa motsamao o otlolohileng |

| Bongata | Lihlopha tse 4 ho tiisoa ka mocheso, lihlopha tse 4 ho pholile |

| Bolelele | 700 limilimithara |

| B sesebelisoa sa zip se otlolohileng | |

| Sebopeho | paatsepama e bontšang tšepe tobetsa, tsidifatso kopano selemo tobetsa sebopeho, tlase ho tiisa thipa; mocheso oa ironing holder pneumatic e theohela tlase ha mochini o emisoa. Seta bocha ha mochini o qala. |

| Khanna | mochini o ka sehloohong o khanna coupling rod ea eccentric mechanism ho etsa motsamao o otlolohileng |

| Bongata | Lihlopha tse 2 tse tiisitsoeng ka mocheso, lihlopha tse 2 li sebetsa ka ho pholile |

| Sesebelisoa sa ho tiisa se rapameng | |

| Sebopeho | rapameng bontša tšepe tobetsa kopano sebopeho sa selemo, tsidifatso kopano |

| Khanna | mochini o ka sehloohong o khanna coupling rod ea eccentric mechanism ho etsa motsamao o otlolohileng |

| Bongata | lihlopha tse tharo holim'a ho tiisoa ha mocheso, lihlopha tse peli holim'a ho pholile |

| Bolelele | 640 limilimithara |

| B Sesebelisoa sa ho batalla se otlolohileng (mocheso o batang oa zip e bohale) | |

| Sebopeho | rapameng pontšong tšepe tobetsa kopano sebopeho sa selemo |

| Khanna | ho tshoana le ho tiisa ho tshekaletseng |

| Bongata | 2 e beha ka ho hatella mocheso |

| Sesebelisoa sa ho fepa lifilimi | |

| Sebopeho | rabara rolara ho hatella mofuta wa khohlano |

| Khanna | servomechanism ea tlhahiso ea metsi e tsoang kantle ho naha (Panasonic, Japan) |

| Phetiso | lebidi la synchronous le lebili |

| Mokhoa oa ho laola | taolo ea centralized PLC, ho lokisa bolelele ba synchronous le taolo ea tsitsipano e bohareng |

| Khatello e bohareng | |

| Sebopeho | phaphametseng tsitsipano moqolo sebopeho |

| Mokhoa oa ho laola | taolo e bohareng ea PLC |

| Mokhoa oa ho laola | mokhoa o tlatsetsang oa motsamao o phaphametseng oa lirolara o laola bolelele ba mohato oa servo ho fihlela ho emisa le ho qala ka nako e le 'ngoe. |

| Mokhoa oa teko | electromagnetism approaches switch (NPN) |

| Phetoho e fapaneng ea tsitsipano | 0.1-0.2mm (setting ea k'homphieutha, matšeliso a itekanetseng) |

| Sesebelisoa sa phetiso e kholo | |

| Sebopeho | crank rocker push and pulling coupling rod sebopeho |

| Khanna | 3KW Panasonic servo enjene. |

| Phetiso | mochini o tsamaisang motlakase o ka sehloohong sehlopha sa 1: 10 reducer |

| Mokhoa oa ho laola | taolo e bohareng ea PLC |

| Mokhoa oa ho matha | main motor running drives foreimi ho etsa motsamao o otlolohileng |

| Sesebelisoa sa ho beha maemo ka boiketsetso | |

| Mokhoa oa teko | tlhahlobo ea tlhahlobo ea sensor ea photoelectrical ea reflection |

| Ho nepahala ha teko | 0.01- 0.25mm |

| Ho nepahala ha boemo bo kopaneng | ≤0.5-1mm |

| Sebaka sa ho batla ka lifoto | ± 3 limilimithara |

| Ho lokisa maemo a lekanang | ± 3 limilimithara |

| Ho beha maemo a ho lokisa ka bohlale | Lipina tsa servo tse leka-lekaneng hajoale, sistimi ea ho lokisa ea othomathike ea photoelectrical |

| Tlhophiso ea ho laola mocheso | |

| Mokhoa oa teko | teko ea banyalani ba thermo |

| Mokhoa oa ho laola | taolo e bohareng ea PLC, phetoho ea PID, phetisetso e tiileng ea mmuso |

| Boemo ba maemo a mocheso | e tloaelehileng -360 ℃ |

| Sebaka sa tlhahlobo ea mocheso | karolo e bohareng e futhumatsang motlakase |

| Thipa e sehang habeli (Moveable double cutting) | |

| Sebopeho | thipa e sehang holimo + lisebelisoa tsa ho lokisa + thipa e tsitsitseng e ka tlase |

| Mokhoa | thipa ea ho kuta ka selemo |

| Phetiso | koloi e ka sehloohong, mochine oa eccentric ho ea holimo le tlase. |

| Phetoho | ts'ebetso e otlolohileng (lipheletsong tse peli) |

| Sesebelisoa sa mokotla se emeng |

| Sistimi ea othomathike ea "synchronous unwind", tokiso ea mahala ea tsitsipano e khutsitseng, ho phutha ka makhetlo a mararo. |

| Automatic chitja mekoti pouching sesebelisoa le boemo bo nepahetseng. |

| Sesebediswa sa ho itokolla ka zip ka othomathike |

| Lebelo la "gearbox" le ikemetseng le ikemetseng le fokotsang phepelo ea enjine |

| Phetoho e ikemetseng ea photoelectric e netefatsang lebelo la synchronous le enjene ea mantlha |

| Sesebelisoa sa ho phunya (se sebelisa likarolo tse tsoang kantle ho naha) | |

| Sebopeho | inama e tšehetsang enjine ea pneumatic e etellang pele sebopeho sa tšusumetso ea mohlala |

| Mokhoa oa ho laola | taolo e bohareng ea PLC |

| Khanna | Solid-state relay e tsamaisa boleng ba solenoid |

| Bongata ba sebaka sa ho phunya | lihlopha tse peli tsa motheo (rhombus) |

| Moqomo oa moea | Airtac, Taiwan |

| Sesebelisoa sa thipa ea welding | |

| E tšekaletseng: | 20mm * 2 radix; 30mm * 2 radix; 40mm * 2 radix; 50mm * 2 radix |

| Khutlisetsa morao | |

| Phepelo ea motlakase | mekhahlelo e meraro 380V, ± 10%, 50HZ mela e mehlano |

| Bolumo | 45KW |

| Phepelo ea moea | khatello ≥ 0.6Mpa |

| Metsi a pholileng | 3 L / mets |