Lilemong tsa morao tjena, tsoelo-pele ea mechine e sebelisoang hape e fetotse mekhoa ea indasteri ea ho tsosolosa, ho etsa hore e sebetse hantle, e boloke chelete le tikoloho. Theindasteri ea ho tsosolosats'ebetso e na le karolo ea bohlokoa ho fokotsa litšila le ho baballa mehloli ea tlhaho 'me e kenyelletsa ho bokella, ho hlopha, ho sebetsa le ho etsa lihlahisoa tse ncha. Ts'ebetso ena ha e thuse feela ho fokotsa tšusumetso ea litšila tikolohong empa e boetse e tlatsetsa tšebelisong e tsitsitseng ea lisebelisoa.

Mechini ea ho recycle e kenyelletsa mefuta e mengata e fapaneng ea lisebelisoa le mahlale a etselitsoeng ho iketsetsa le ho beha mabaka methating eohle ea ts'ebetso ea ho recycle, ho tloha ho hlophisoa ha thepa le ho senya ho ea ho granulation ea lebokose la baling, e ntlafatsang haholo katleho le tlhahiso ea ts'ebetso ea ho tsosolosa. Ha re shebisiseng ka botebo lintlha tsa bohlokoa tsa tšebetso ea indasteri ea ho recycle hape 'me re hlahlobe hore na mochine oa ho recycle o fetola joang tsamaiso ea litšila e tsitsitseng.

Mohato oa pele oa tšebetso ea liindasteri ke ho bokella le ho hlopha lisebelisoa tse ka sebelisoang hape. Ka tloaelo, sena se ne se hloka mosebetsi oa matsoho le lisebelisoa tsa motheo tsa ho hlopha, leha ho le joalo, ka ho fihla ha mechine e tsoetseng pele ea ho tsosolosa, mokhoa ona o fetohile o rarahaneng haholo le o nepahetseng. Mekhoa ea ho hlopha e ikemetseng e nang le li-sensor, mabanta a conveyor le li-scanner tsa optical li ka khetholla le ho arola mefuta e fapaneng ea thepa e kang polasetiki, likhalase, pampiri le litšepe ka nepo e phahameng. Sena ha se fokotse feela ho itšetleha ka mosebetsi oa matsoho, empa hape se netefatsa bohloeki bo phahameng ba lisebelisoa tse ka sebelisoang hape, ho li etsa tsa bohlokoa haholo 'marakeng.

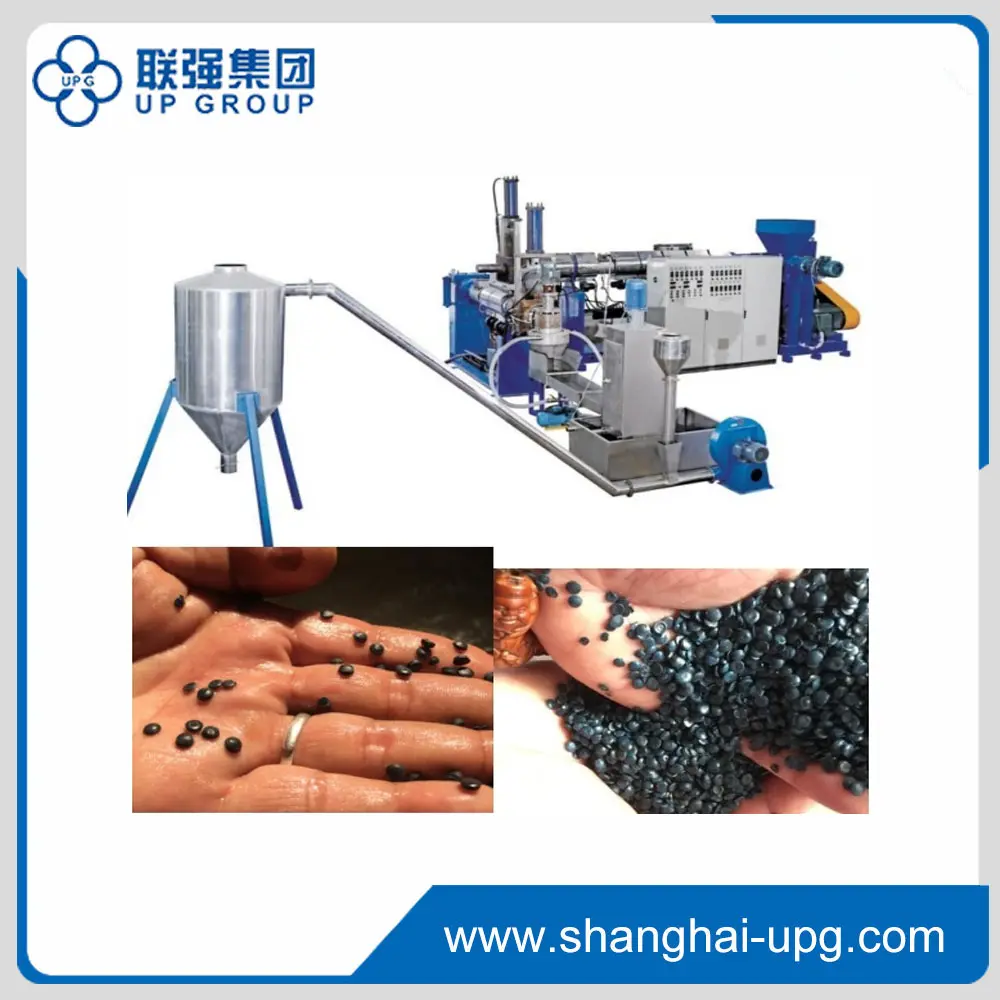

Re lumelle ho u tsebisa ka e 'ngoe ea mechini e sebelisoang hape e entsoeng ke k'hamphani ea rona.LQ-150/200 china bahlahisi ba mochini oa polasetiki oa polasetiki oa PE o ikemetseng ka botlalo

Ke lisebelisoa tse loketseng tsa indasteri ea polasetiki. E bonolo haholoanyane ebile e bonolo ho e lokisa, boloka basebetsi le litšenyehelo ho ts'ehetsa bareki ba rona ho etsa ka mokhoa o atlehileng haholoanyane.

Hang ha lisebelisoa li hlophisoa, lia siloa ebe li siloa ho li qhetsola likotoana tse nyane le likaroloana, 'me ke hona moo metjhini e nchafatsang, joalo ka li-shredders le li-granulator tsa indasteri, e bapalang karolo ea bohlokoa. Mechini ena e khona ho sebetsana le mefuta e mengata ea lisebelisoa, joalo ka polasetiki, rabara, lehong le tšepe, e be li-granules kapa li-flakes tse tšoanang, 'me thepa e sithabetseng e bonolo ho sebetsana le eona, ho tsamaisa le ho tsoela pele, e leng ho loketseng haholoanyane ho tsosolosa le ho tsosolosa.

Lipolasetiki le ho tsosolosoa ha likhalase, ho hloekisa le ho omisa ke mehato ea bohlokoa ea ho tlosa litšila le litšila tse tsoang litšila. Mechini ea ho hlatsuoa le lisebelisoa tsa ho omisa li etselitsoe ho hlatsoa le ho omisa lisebelisoa ho netefatsa hore li fihlella litekanyetso tsa boleng tse hlokahalang bakeng sa ho sebelisoa hape. Mechini ena ha e ntlafatse bohloeki ka kakaretso ba lisebelisoa tse khutlisitsoeng, hape e khothaletsa paballo ea metsi le ts'ireletso ea tikoloho ka ho sebelisa metsi le matla a ho sefa.

Thepa ea baling le compaction e sebelisoa ho hatella le ho paka thepa e lokisitsoeng hore e be libale tse teteaneng, tse bonolo ho li tšoara kapa liforomo tse hokahaneng. Mohlala, hangata li-balers li sebelisoa ho kopanya lisebelisoa tse kang khateboto, pampiri, lipolasetiki le litšepe hore li be libale tse thata tse ka bolokoang habonolo, tsa tsamaisoa le ho rekisetsoa litsing tsa ho sebelisoa hape. Ka mokhoa o ts'oanang, li-compactor li sebelisetsoa ho fokotsa bongata ba thepa e kang foam, polasetiki le masela, ho ntlafatsa sebaka sa polokelo le ho ntlafatsa katleho ea lipalangoang.

Bakeng sa lisebelisoa tse ling, joalo ka lipolasetiki, lits'ebetso tsa pelletising le extrusion li sebelisoa ho fetolela lipolasetiki tse khaotsoeng kapa tse entsoeng ka pellet hore e be li-pellets tsa junifomo kapa lihlahisoa tse extruded. Mechini e sebelisoang hape joalo ka li-pellets le li-extruder li sebelisa mocheso le khatello ho qhibiliha le ho etsa li-pellets tsa polasetiki hore li be libopeho tse ncha tse ka sebelisoang ho etsa lihlahisoa tse ngata tsa polasetiki. Mokhoa ona o koetsoeng oa ho nchafatsa lipolasetiki ha o fokotse feela ho itšetleha ka lipolasetiki tse sa bonahaleng, empa hape o fokotsa tšusumetso ea tikoloho ea litšila tsa polasetiki.

Ka kakaretso, ho kenyeletsoa ha mechini e sebelisoang hape tšebetsong ea indasteri ea ho e sebelisa hape ho ka ntlafatsa haholo ts'ebetso, boleng le botsitso ba mekhoa ea taolo ea litšila. Theknoloji ena ea chelete ha e nolofatse mokhoa oa ho e sebelisa hape, empa hape e bula menyetla e mecha bakeng sa lik'hamphani ho iqapela le ho theha boleng ho tsoa ho thepa e sebelisoang hape. Ha tlhoko ea litharollo tsa taolo ea lithōle e ntse e hola, karolo ea mochini oa ho recycle ho ea pele indastering e ke ke ea nyatsuoa. Ho hlakile hore nts'etsopele e tsoelang pele le ho amoheloa ha mechini e sebelisoang hape ho tla bapala karolo ea bohlokoa ho bopeng bokamoso ba ho e sebelisa hape le paballo ea lisebelisoa lefatšeng ka bophara. E mong le e mong o amohelehile hoikopanye le k'hamphani ea ronaka nako e nepahetseng haeba u na le tlhoko ea mochini o sebelisoang hape kapa lipotso life kapa life tse ikhethileng bakeng sa likeletso, re tla u fa ka pelo eohle lihlahisoa le lits'ebeletso tsa boleng bo holimo.

Nako ea poso: Aug-26-2024